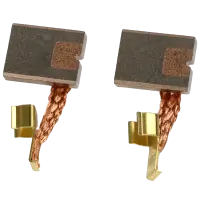

HERMAN HCB carbon brushes:

made of a graphite-based composite, the composition of which depends mainly on the current load at the point of contact of the carbon brush with the commutator and on the speed of the commutator

Balance of conflicting requirements:

sufficient hardness for high carbon life does not reduce the life of the commutator copper laminations

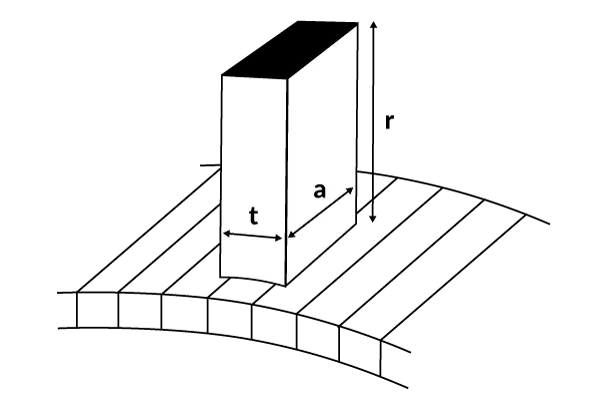

Rounding of the original carbon brush:

at the point of contact with the commutator, it exactly copies its radius and immediately after replacement, it adheres to the collector lamellas with its entire surface

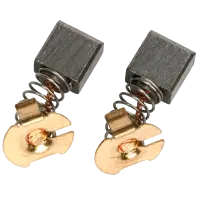

Service life of carbon brushes:

the decisive factors are the net working time of the engine, the number of engine starts and its load. Carbon brushes are consumables and a pair of carbons must be changed at the same time

Let's not forget that carbon brushes are the most stressed part of any rotating machine:

they must withstand friction, elevated temperatures during the passage of current and must be resistant to spark damage. We do not save in the wrong place - a commutator damaged by low-quality carbon is 20 times more expensive. If non-original substitutes are used, it is not possible to apply the guarantee for the tool

International

International

Alena Bartekova –

Rýchle dodanie a veľká spojnost

Eva Longauerová –

Dlho vydržali

Milota Maceková –

-vyhovejú naším požiadavkám

-dlhá výdrž

žiadne

Gejza Molnár –

Nedalo sa to ešťe vyskúšať

Strašík –

Výborne len sa nepokazte ako je na Slovensku zvykom

Štefan Kuba –

Tomáš –

Všetko ako má byť. Uhlíkové kefy presne pasovali. Milo ma prekvapil aj malý darček

Dusan –

Super aj na staršiu utahovacku to sadlo presne

Zdeněk Kmoníček –

druhé uhlíky do vrtaček,které slouží deset let s původními bateriemi,za pár korun.

Neznám jiný stroj s takovou výdrží.