Drill bits for wood – how to choose the right one?

Drill bits for wood are an essential part of any carpenter, craftsman or DIY enthusiast's tool kit and play a significant role in the world of drilling. Their correct selection and use can have a significant impact on the quality and efficiency of drilling, contributing to the successful completion of "wooden" projects.

But first, let's take a closer look at what a drill bit for wood actually is.

It is a woodworking tool characterized by having a centering point and one or more sharp pre-cutting edges around the circumference, which are used to cleanly and smoothly cut through the wood fibers around the hole. This gives the hole a relatively smooth shape. The well-defined cutting edges allow for fast and precise drilling and remain sharp even with repeated use, ensuring consistent drilling results.

Drill bits for wood are made from a variety of materials, each with its own advantages and limitations. The most common is CrV (chrome-vanadium) steel, which is particularly suitable for drilling into soft wood and chipboard. HSS (High-Speed-Steel) drill bits are an improved version of conventional steel drill bits. This combination improves the hardness, strength and durability of the drill bits. This allows them to drill effectively into harder wood.

Fig. 1. Hole after drilling in soft wood

There are several different types of drill bits for wood, each with a different shape and designed for specific drilling tasks. There are 4 basic types based on the method of drilling:

- 1. Twisted drill bits

- 2. LEWIS drill bits

- 3. Flat drill bits

- 4. Forstner drill bits

Twisted drill bits

A twisted drill has a cylindrical shank and a single or double spiral, which ends in two cutting edges, with a centering point in the middle. The spiral-shaped cutting edges help to remove chips and allow for fast and efficient drilling.

Fig. 2. Twisted drill bit for wood

The size of the holes can be easily adjusted by choosing the right drill bit diameter. TIP: for a classic screw connection with a nut, the hole diameter must be slightly larger than the screw diameter. For self-tapping screws, on the other hand, it is advisable to drill a hole with a diameter of about 2mm smaller.

Up to a diameter of 10mm, the shank is the same as the drill diameter, larger diameters have a shank diameter of up to 13mm, so that the drill can be clamped in the chuck of a conventional tool.

It is suitable for general use in both soft and hard wood. NIt can also be found under the name "wood milling drill" or "standard wood drill“.

LEWIS drill bit

The LEWIS wood drill bit has a hexagonal shank, which ensures a firm hold in the tool chuck, and a serpentine spiral, which is why it is sometimes called a "serpentine drill bit for wood".

The spiral is finished with a sharp cutting edge and has a self-centering threaded tip in the center that accurately captures the drill bit at the planned drilling location.

It is used for deep drilling its massive spiral aggressively pulls the drill into the wood. It is suitable for drilling into soft and hard wood. Its properties make it suitable for professional drilling work, such as the installation of trusses, gazebos and other solid wooden structures. It is produced in diameters of 6-32mm with a length of up to 460mm. When drilling larger depths and diameters, it requires powerful tools with a higher tightening torque.

Fig. 3. LEWIS drill bit

Flat drill bit

A flat drill bit usually has a shank with a ¼” external hexagon and is characterized by the fact that instead of a spiral, it has a flat blade, which has sharp pre-cutting edges on both sides and a sharp tip in the center for precise drilling and guiding the drill.

Fig. 4. Flat drill bit for wood

It is used for drilling large diameters needed in carpentry, electrical and installation work.

It is also suitable for creating a countersunk hole that will accommodate any screw and give the wooden unit a clean and smooth appearance. It is suitable for drilling into both soft and hard wood and is most often produced in diameters of 10-40mm.

Its length is usually up to 150mm, but it can be extended with an extension piece up to 300mm long.

Forstner drill bit

The drill shank can be ¼” external hexagon or cylindrical with a diameter of up to 10mm depending on the drill diameter. Instead of a spiral, it has a massive drilling head, the edges and interior of which are formed by 4 large cutting edges. In the center is a centering tip of the drill for precise drilling guidance.

The length of the Forstner drill bit is up to 130mm, as as it is not used for deep drilling.

It is used to produce large diameter holes (10-50mm) and flat blind holes - cabinet hinges or furniture connecting fittings.

A blind hole is a hole that is not drilled through the entire thickness of the material, only to a certain depth. It is mainly used in softwood.

Fig. 5. Forstner drill bit - blind hole

In addition to the basic types mentioned, there are also several special drill bits for wood:

Wood core drills are characterized by their large diameter and are suitable, for example, for drilling holes for sockets or small hallway lights.

Step drill bits for wood are designed for drilling large holes in thin-walled wooden boards. The advantage is that only one drill bit is needed and we do not have to use a whole set of classic drill bits.

The mortise drill bit bit is used for mortising various rectangular holes or recesses.

A countersink drill bit for wood helps align the screw head with the surface of the board.

Tool R.P.M.

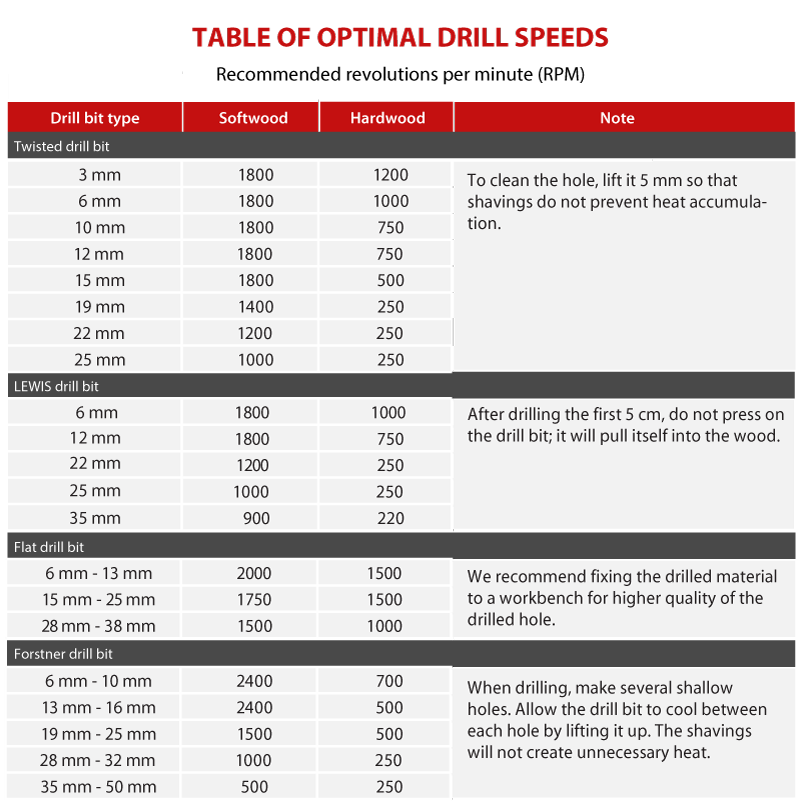

When drilling into wood, we should know with what R.P.M. we need to drill at in order to drill effectively and correctly. At low R.P.M.-s, the quality of the drilled hole will decrease, at high speeds, the surface of the drilled hole will burn and the drill will get damaged. The optimal RPMs for drilling into soft and hard wood can be found in the table. It is good to follow them at least approximately. In practice, it is not possible to determine the number of revolutions with the naked eye, but we can use the information about the maximum number of revolutions on the tool label. Using the speed regulator, we can then adjust the speed as needed.

Keywords: wood drill bit, twist drill bit, flat drill bit, snake drill bit, Forstner drill bit

Sources:

HERMAN internal technical and training materials

https://de.wikipedia.org/wiki/Holzbohrer#Kunstbohrer/_Zylinderkopfbohrer

International

International

Csaba Kiss –

Könnyen érthető szakszerű magyarázat.Hasznos volt és érdemes elovasni!

Easy to understand professional explanation. It was useful and worth reading!

Translate text Zobraziť originálJakub Borsík –

zaujímavý článok aj keď veľa ľudí má jeden vrták na všetko.

interesting article although many people have one drill for everything.

Translate text Zobraziť originál